Fundamentally, all electric motors convert electrical energy into rotational kinetic energy by exploiting the laws of electromagnetism. But these physical rules have given rise to a variety of motor architectures, which offer very different performance characteristics. In this article, we take a look at the two most common motor designs: brushed and brushless motors.

5 Reasons Brushless Motors are Better than Brushed Motors

April 13, 2021Brushed Motors

The relatively simple brushed motor was the first type of electric motor to attain widespread use.

A brushed motor essentially consists of two parts: a stator and a rotor. The stator is made up of a stationary ring of permanent magnets. The rotor, which sits inside of the stator, consists of a ring of electromagnetic windings whose ends are connected to a commutator. The commutator is in constant contact with brushes that are fixed on opposing sides. Supplying direct current to the electromagnetic windings in the rotor induces a magnetic field, and it will naturally rotate until it aligns with the magnetic field of the stator.

To enable constant rotation of the rotor, the polarity of the electromagnetic windings must be alternated by cycling current through the different phases of the windings. This process is known as commutation. In brushed motors, DC current is supplied from the fixed brushes to the commutator. By turning on and off the current in a particular sequence, you can induce constantly rotating magnetic fields, which cause the rotor to spin.

Brushless Motors

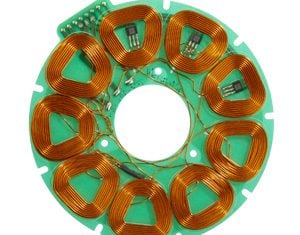

Brushless motors do away with brushes; instead using electronics to commutate the motor. In brushless motors, an electronic circuit (example: Optical encoder or Hall-Effect sensors) senses the position of the rotor relative to the stator and supplies current through the three phase pairs of the stator windings, maintaining a 120° phase offset between each, to ensure smooth rotation and low torque ripple. Brushless motors are a comparatively recent motor design, made possible by the development of solid-state electronics in the 1960s.

Though the electronics involved in brushless motors are simple by todays’ standards, they represent a radical departure from the mechanical commutation systems found in brushed motors. This design change gives brushless motors a surprising number of advantages.

1. Quieter Motor Operation

Friction and electrical arcing between brushes and commutator plates in brushed motors produce substantial motor noise. In brushless motors, the job of commutation is carried out by an electronic circuit, resulting in much quieter operation.

2. Less Heat Production of the Motor

As well as producing sound, friction between the brushes and commutator plates in a brushed motor produces a significant amount of heat. This can be a serious problem in many applications. In brushless motors, the only friction that occurs is in the rotor bearings. This means heat production is much less of an issue in brushless motors.

3. Higher Motor Efficiency

This is a particularly important advantage of brushless motors. The sound and heat produced by a brushed motor essentially represent power losses from the device, taking energy away from the rotor itself – which would be used to drive the load. In brushless motors, the amounts of sound and heat produced are greatly reduced, resulting in significantly higher efficiency.

4. Longer Motor Life

The brushes in brushed motors are gradually worn away with use, since they are in constant contact with the commutator – it is only a matter of time until the brushes need to be replaced. Brushless motors do not face this problem, which drastically reduces maintenance requirements, and enables a range of applications where brush replacement would be impractical, such as in outer space satcom equipment.

5. Better Power-to-Weight Ratio of a Motor

Fewer mechanical components means brushless motors have lower mass than brushed motors. The result: brushless motors offer a better power-to-weight and torque-to-weight ratio than brushed motors.

All of these advantages mean that, aside from a few legacy uses, brushless motors reign supreme for present-day applications. Contact a member of the Celera Motion team to learn more about our Applimotion range of direct drive brushless motors.