What are Air Bearings?

Air bearings are a type of bearing that utilize a non-contacting system where a gas film (usually air) acts as the lubricant that separates two surfaces in relative motion – typically a rotating shaft, and a stationary radial journal or axial thrust bearing. The unique design creates a frictionless surface and enables the moving parts to operate seamlessly without experiencing wear.

In the quest for higher productivity, greater accuracy, and longer product life, machine tool and robotic arm OEM’s are constantly pushing the limits of spindle technology fitted to their equipment.

Conventional bearing systems, usually ball bearings, cannot always deliver the very high speeds demanded by these industries while still maintaining high rotational precision, thermal stability, and long service life. This is primarily due to the mechanical contact between the balls and the races, which can result in rapid wear and excessive heat generation at high D/N ratios, leading to a loss in accuracy and even premature failure of the bearing.

In addition, many advanced industries require oil free bearing systems to avoid workpiece contamination, particularly in a clean room application.

For many high technology industries, an air bearing spindle is the perfect solution.

There are two main kinds of air bearing technologies;

Aerostatic Air Bearing

- Externally pressurized: a separate external supply of air is fed under pressure between the two surfaces being kept apart.

- It is a continuous flow system where pressurized gas from the source flows through restrictors into the clearance between the bearing surfaces, escaping to the atmosphere at the outside edges of the bearing.

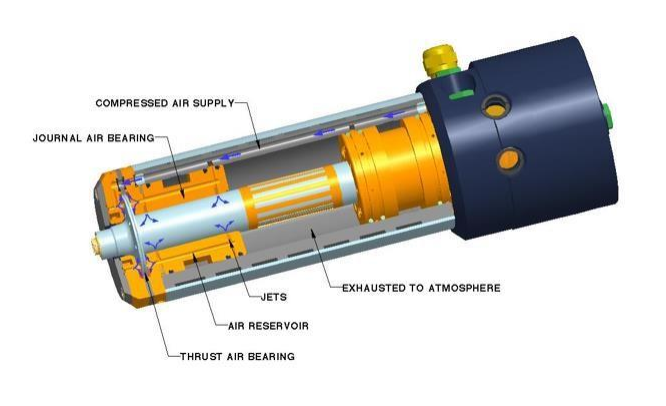

- There are several types of restrictors, used in aerostatic bearing designs: simple orifice fed, pocketed orifice, slot fed, and porous. The sections below in Figure 1 show a typical orifice journal bearing design.

Figure 1

Celera Motion’s Westwind aerostatic journal and axial bearings

Aerostatic Air Bearing

- Self-generating: the supporting film is generated by the relative motion of the two surfaces being kept apart.

- An aerodynamic bearing can be of several types. The design characteristics differ greatly between journal and axial bearings, and they can suffer problems of instability.

- Types: simple cylinders, tri-lobe, grooved (axial / herringbone / spiral) and stepped.

The patented aerodynamic radial bearing consists of a cylindrical shaft rotating inside a non-circular journal, in this case trilobed, to generate areas of high pressure (where the shaft runs closest to the journal) once the shaft is rotated at sufficient speed. A low friction coating on the journal protects the initial contact rubbing before the air film is created.

Cross section through an aerodynamic radial bearing

Figure 2

Celera Motion’s Westwind aerodynamic axial bearing showing spiral grooves

Figure 3

The construction of a typical high speed air bearing is shown below in Figure 4. In this particular design the axial, or thrust bearing is located at the front of the spindle and is integrated into the front radial journal bearing. The motor rotor is located between the two radial bearings and the whole spindle body is surrounded by a water cooling jacket. The airflow can be seen diagrammatically by following the blue arrows through the spindle.

Cutaway of Celera Motion’s Westwind air bearing PCB Drilling & Routing Series spindle

Figure 4

For air bearings to perform correctly, they must be manufactured to extremely precise tolerances. The diagram in Figure 5 compares the relative sizes of a typical air bearing radial clearance with some other more well-known objects, such as a human hair and a dust particle.

Figure 5

The following table acts as a guide to highlight where the benefits of the Celera Motion Westwind air bearing exceed the other more conventional bearing types.

Further Reading