What is a resolver?

A resolver is an electrical transformer used to measure the angle of rotation. Many resolvers look somewhat like an electric motor comprising of copper windings on the stator and a machined metal rotor.

How does a resolver work?

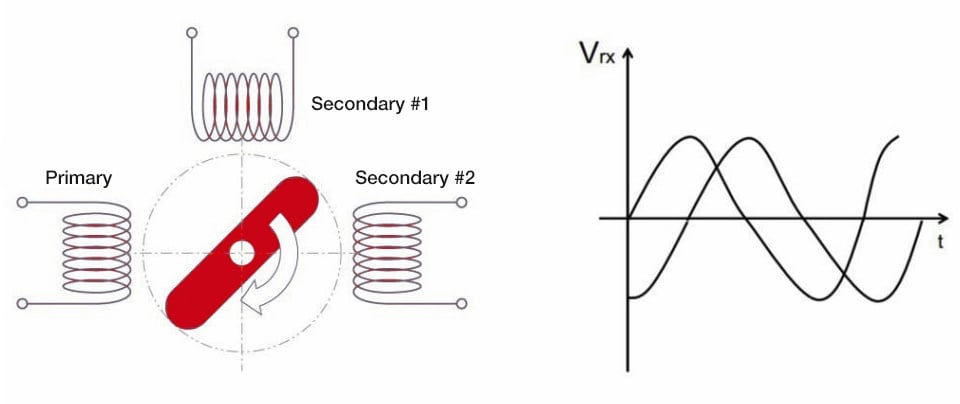

A resolver uses the same basic physical principles as an electrical transformer. Resolvers typically use copper windings in its stator and a machined metal rotor. The inductive coupling between the windings varies according to the angular position of the rotor. The resolver is energized with an AC signal and the resulting output from the transformer windings is measured to provide an electrical signal which is proportional to angle.

A typical resolver has three windings – a primary winding and two secondary windings. The windings are created using copper wire and are formed on the resolver’s stationery element – the stator. The primary wire acts as the input for an AC drive signal and each of the secondary windings are used as pick up or receive windings. In the diagram above, the rotor is made from a material such as steel or iron and is arranged relative to the windings and therefore will couple varying amounts of energy into the secondaries depending on its angle of rotation.

Types of Resolver

There are a variety of types of resolver:

- Brushless resolver

- Slab resolver

- Pancake resolver

- Receiver resolver

- Differential resolver.

Resolvers have an established reputation for accuracy and reliability and are often the automatic choice for safety-related applications. The use of copper windings and metal elements means that resolvers are robust and heavy, bulky, and expensive.

In recent years, a new generation of devices has become popular – the inductive encoder. Inductive encoders, such as IncOders made by Celera Motion, use the same physics as a resolver but are less costly, lighter, more compact, and accurate. Rather than the traditional resolver’s copper windings, inductive encoders use printed circuit boards as their main element.

Resolvers – Strengths and Weaknesses

| Strengths | Weaknesses |

| Reliable, robust, accurate, long life, tolerant to misalignment | Bulky, heavy, expensive, needs skilful specification and implementation |

Further reading on resolvers and resolver sensor alternatives

How Inductive Sensors Work

Ultra IncOder Inductive Angle Encoders

IncOder Inductive Angle Encoders

Resolvers, Frameless Resolvers, Direct Drive Motors, Ring Encoders

Slab resolvers

Pancake resolvers

Resolvers vs IncOder technology

Resolver Alternatives