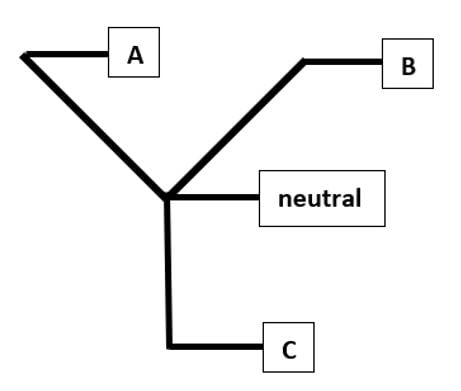

Wye windings have four nodes:

- A phase

- B phase

- C phase

- Neutral

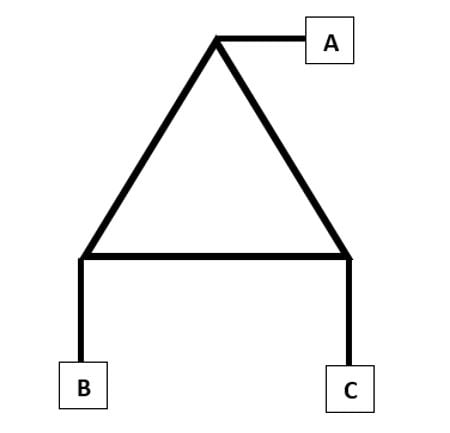

Delta windings have three nodes:

- A phase

- B phase

- C phase

The connection schematic for a Wye winding is a star or “Y” shape, and the connection schematic for a Delta winding is a triangle shape. See figures 1 and 2 below for each winding type.

Figure 1 Wye Winding Connection Diagram

Figure 1 Delta Winding Connection Diagram

Not all motors have perfect impedance. Delta-wound motors have small impedance errors that can induce circulating currents. These currents cause heating in the motor and higher order noise in the back-emf waveform. This greatly affects the smoothness of rotation at lower speeds, which is detrimental to precision systems. Wye-wound motors also have small impedance errors, but because of the connection configuration, they do not experience the same negative effects. Celera Motion motors use a Wye winding to avoid the circulating parasitic currents while enabling smooth rotation at low speeds and lower torque ripple.