Applimotion motors and actuators utilize rotary and linear brushless motor technology to create unique motion solutions. While brushless motors have been around for a very long time, the detailed application of this technology has countless variants. Our engineers work closely with our customers to understand their application and create an optimized solution. We provide frameless motor kits to support the maximum level of integration into customer’s machines, as well as fully integrated sub-system solutions. The Applimotion direct drive motors and stages are the product of unparalleled application expertise and performance-driven design.

Frameless Motor Kits

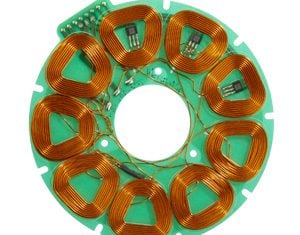

Frameless motor kits are motor assemblies that do not include housings and only include a stator and rotor. A back iron can be included, which completes the magnetic circuit of the motor kit. The stator and rotor can be embedded directly into custom mechanisms, allowing greater flexibility and direct connection to the inertia load.

Fewer components are needed for frameless motor kits compared to traditional housed motors, reducing the need for maintenance while increasing reliability, resulting in less downtime and lower repair cost.

Permanent Magnet Synchronous Machines (PMSM)

In PMSM, current flowing through the windings of the stator is synchronized, creating an electromagnetic field that interacts with the permanent magnets in the rotor. This works to create torque for the rotor to move in rotation.

“Permanent magnet synchronous machine” is the correct term to describe both brushless DC (BLDC) and brushless AC motors (BLAC).

BLDC motors are, by definition, associated with a trapezoidal back emf waveform, and are typically driven with six state trapezoidal drives. This motor and drive pairing inherently create significant (~14%) torque ripple due to the six-step commutation method. A need for very low torque ripple in precision velocity and positioning applications prompted the evolution of BLAC motors.

BLAC motors have a sinusoidal back emf waveform and are commonly paired with a sine drive to create low torque ripple output. Either motor type can be paired with either drive type, but a BLAC motor with a sine drive creates the lowest ripple torque profile. Applimotion direct drive frameless motors are BLAC.

Slotted Stators (Motors)

Slotted stators have iron teeth with stacked laminations. These laminations are thin sheets of iron stacked on top of each other, designed to help reduce Eddy Currents throughout the iron core, reducing core power losses. An effect of the iron teeth can be pulsatile detent disturbances during rotation called “cogging torque.” Copper windings are wound around the teeth of the stator. Each tooth has a magnetic field and an inherent attraction to a single pole of the rotor. Cogging torque influence can be more prevalent at low speed because the total system inertia at high speed can “mask” cogging torque disturbances.

Slotless Stators (Motors)

Slotless stators have no teeth in the lamination stack, thereby eliminating the tooth to magnet attraction that causes cogging. Windings are structurally supported by encapsulating them in a potting material or epoxy resin. The lack of iron teeth in the winding area means slotless motors have higher flux leakage and generally have lower torque density. However, they benefit from having fewer speed-dependent losses, making them ideal for ultra-smooth, high-speed applications. Slotless technology is affective in direct drive precision systems because all torque is a function of phase current, and there are no unwanted or uncontrolled torque disturbances in slotless motors.

Direct Drive Frameless Motors

Need help finding a motor?

There are many names used for motor technology. To assist you with the motor selection process, choose the term below that best describes what you’re looking for, and we’ll provide information on how we can help.

I’m looking for more information on…

Custom Mechatronics

Applimotion products were built on the foundation of electromagnetic and mechanical engineering expertise. We have used this expertise to produce thousands of solutions for our customers over the past 20 years. Our product range covers rotary, limited angle, long and short stroke linear motion – delivering very low profile and large through hole solutions. These products can be customized to suit your specification needs.

The in-house mechatronics team is expert in packaging our Applimotion, MicroE, Zettlex, Ingenia, and Westwind products into fully integrated solutions.