Introduction

Often when picking the right motor for an application, we refer to datasheets for motor specifications, such as continuous torque, continuous current, motor constant or torque constant. While it is easy to take these values and assume they are true for your application, you must pay attention to the type of units that are listed with those specifications. In the world of motion control, units can vary significantly depending on drive type. The type of drive being used in the system can be a sinusoidal drive or a trapezoidal (six-step) drive. Knowing the type of drive being used in the system allows you to determine what motor units are needed. This paper will walk you through motor unit conversions to get the units you need for your drive type.

Torque Constant

When selecting a motor, you will see several parameters listed on the datasheet that characterize each motor. One of those specifications is the torque constant. The torque constant (𝐾𝑡) reflects the amount of torque a motor can output per unit of current. It is helpful for calculating the peak or continuous torque when a peak or continuous current value is known, and vice versa.

𝐾𝑡 is derived from the equation shown below:

By dividing torque by current, you can calculate for 𝐾𝑡 :

Based on this equation, the units for 𝐾𝑡 are

However, we are still missing one critical piece of information. Depending on the type of drive, either trapezoidal or sinusoidal, the required units for 𝐾t will vary. For example, if you are using a trapezoidal drive, the current supplied to the motor will be direct, rather than alternating. Therefore, the unit for current will be 𝐴DC and the torque constant, which is referred to as 𝐾ttrap in this case, will have units of

If you are using a sinusoidal drive, which is more common when paired with a direct-drive brushless AC motor, the current supplied to the motor will be alternating. Therefore, the unit for current will be 𝐴pk-sine and the torque constant, now Ktsine will have units of

Sinusoidal versus Trapezoidal Commutation

Alternatively, the current can be calculated as 𝐴RMS or root-mean-square. Since the average of an AC value would always be zero, RMS helps to provide an effective value for an AC signal, and can then be easily compared to DC signals.

If an RMS value is needed, see the conversions in the following section to calculate for the RMS Current or RMS 𝐾t.

Converting Between Units

If you have a sinusoidal drive, but the motor datasheet only specifies trapezoidal units (Kttrap> or 𝐴DC), you will need to convert these parameters to have sinusoidal units, making sure that the drive can fully support the motor. If you do not convert to the correct units, it is possible that the motor will be under-rated or over-rated and will not meet the performance requirements of your system.

To convert between units for current, use the following equations:

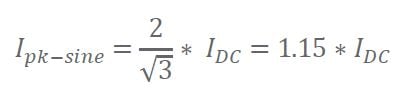

Current – DC to Peak of Sine

Current – Peak of Sine to RMS

To convert between units for motor constant, use the following equations:

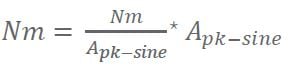

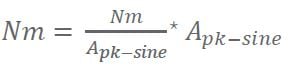

Motor Constant – Peak of Sine to DC

Motor Constant – DC to RMS

Motor Constant – RMS to Peak of Sine

Using these equations, you will be able to determine the rated current of the motor in the proper units according to your drive.

Below are examples of motor unit conversions and basic calculations that may help in your motor selection process.

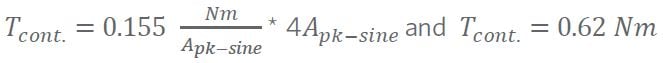

1. We have a sine drive and we know the 𝐾𝑡sine of the motor is 0.155 Nm/𝐴𝑝k-sine. The sine drive datasheet specifies a current of 4𝐴𝑝k-sine. Let’s calculate the continuous torque of the motor.

Tcont.= 𝐾𝑡sine * Ipk-sine

In units, this equates to

Therefore

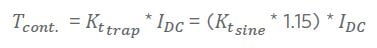

2. Now let’s look at an example where you have a trap drive and the drive datasheet rates the current at 3.464 𝐴DC , but the motor datasheet specifies the 𝐾𝑡 for a sine drive (𝑁m /𝐴𝑝k-sine) at 0.155. We will calculate the continuous torque of the motor by converting 𝐾𝑡sine to 𝐾𝑡trap.

In units, this equates to 𝑁m = (𝑁m /𝐴DC)* 𝐴DC

Therefore

3. Lastly, let’s look at an example where you have a sine drive, datasheet units for a trap drive, and want to know what the continuous torque will be. The motor datasheet specifies a 𝐾𝑡trap of 0.178 𝑁m /𝐴DC and the drive datasheet lists a current of 2.83 𝐴RMS.

In units, this equates to 𝑁m = 𝑁m /𝐴𝑝k-sine* 𝐴𝑝k-sine

Therefore,

Conclusion

As demonstrated in this paper, motor units are crucial for properly sizing a motor. If the units are not complimentary to the drive, then you may mistakenly select a motor that will not meet the system requirements. Use the equations in this paper to quickly convert between current and torque constant units when necessary. In doing so, you will ensure that the motor you have selected will be compatible with your drive and will perform as expected.